Floor moisture testing determines if your subfloor’s moisture levels are suitable for new flooring installation.

Getting accurate moisture readings helps prevent expensive problems like warping, cupping, and mold growth after installation.

This quick guide covers essential moisture testing methods, acceptable moisture levels, and steps to ensure your flooring installation succeeds.

Why Moisture Testing Matters

Excess moisture in subfloors can cause adhesive failures, dimensional changes, and permanent damage to your new flooring.

Different flooring materials have specific moisture tolerance levels that must be met before installation.

- Wood flooring: 6-12% moisture content

- Concrete subfloors: 3-4% moisture content

- Vinyl and laminate: Usually requires less than 2.5% moisture content

Professional Testing Methods

Calcium chloride testing measures moisture vapor emission rates (MVER) in concrete subfloors.

Relative humidity (RH) testing uses in-situ probes to measure moisture levels within concrete.

Electronic moisture meters provide quick readings for wood subfloors.

DIY Testing Options

Simple plastic sheet test: Tape a 2×2 foot clear plastic sheet to the floor for 24 hours – condensation indicates moisture issues.

Surface moisture meters: Available at hardware stores for around $30-100.

pH testing strips: Check concrete alkalinity which can affect adhesive performance.

Acceptable Moisture Levels by Flooring Type

| Flooring Type | Maximum Moisture Content |

|---|---|

| Solid Hardwood | 6-9% |

| Engineered Wood | 8-12% |

| Laminate | 2.5% |

| Vinyl | 2% |

| Carpet | 5% |

Moisture Problem Solutions

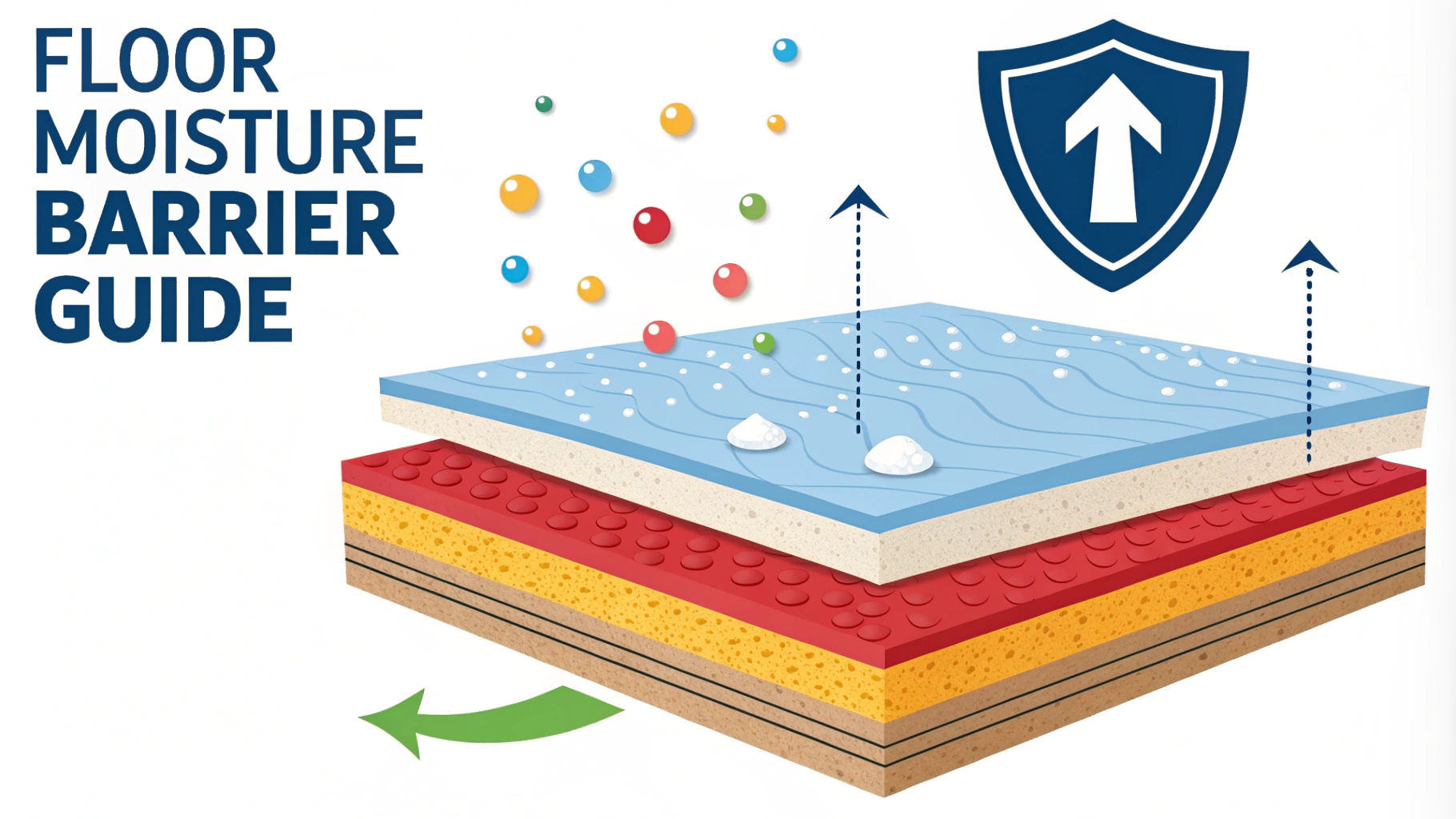

- Install vapor barriers or moisture membranes

- Use dehumidifiers to reduce ambient moisture

- Apply moisture-blocking sealers

- Fix any plumbing or drainage issues

- Allow proper concrete curing time (minimum 60 days)

Professional Testing Services

Contact the National Wood Flooring Association (NWFA) at 800-422-4556 to find certified moisture testing professionals.

The International Concrete Repair Institute (ICRI) maintains a directory of concrete moisture testing specialists.

Next Steps for Your Project

Schedule moisture testing at least 2-3 days before planned installation.

Document all test results and share them with your flooring installer.

Consider professional testing for large projects or when installing expensive flooring materials.

Important Installation Tips

Allow flooring materials to acclimate in the installation space for 48-72 hours before installation.

Maintain consistent room temperature and humidity levels during testing and installation.

Document environmental conditions including temperature, humidity, and weather patterns.

When to Delay Installation

- Moisture readings exceed manufacturer specifications

- Active water leaks or plumbing issues

- Recent concrete pours (less than 60 days old)

- Visible mold or mildew growth

- Failed moisture barrier systems

Common Moisture Testing Mistakes

Skipping multiple test locations across the installation area.

Not allowing sufficient time for accurate readings.

Using incorrect testing methods for specific flooring types.

Ensuring Long-Term Flooring Success

Proper moisture testing is a critical investment in your flooring project’s success.

Document all test results and maintain records for warranty purposes.

Consider seasonal moisture variations when planning installation timing.

Follow manufacturer guidelines for ongoing maintenance and moisture control.

FAQs

- What is moisture testing and why is it important for flooring installation?

Moisture testing determines the amount of moisture content in concrete subfloors or wood substrates. It’s crucial because excess moisture can cause flooring failure, warping, cupping, and mold growth. - What are the main methods for testing moisture in concrete slabs?

The primary methods are calcium chloride testing (ASTM F1869), relative humidity testing (ASTM F2170), and electronic moisture meters. The RH test is considered most reliable for concrete. - How long should I wait to test moisture in new concrete?

New concrete should cure for a minimum of 28 days before conducting moisture tests. However, some industry experts recommend 60-90 days for more accurate results. - What is the acceptable moisture level for installing hardwood flooring?

For concrete subfloors, relative humidity should be below 75% RH, and wood subfloors should have moisture content between 6-12%, with less than 4% difference from the hardwood flooring. - How many moisture tests should be performed on a concrete slab?

For calcium chloride tests, perform three tests for the first 1,000 square feet and one additional test for each additional 1,000 square feet. For RH testing, follow similar guidelines with one test per 1,000 square feet. - What environmental conditions are required during moisture testing?

The testing area must be at service conditions for at least 48 hours before testing, maintaining temperature between 65-85°F and relative humidity between 40-60%. - Can I install flooring over a concrete slab without moisture testing?

No, skipping moisture testing voids most manufacturer warranties and risks expensive flooring failures. It’s essential for all professional installations. - What causes elevated moisture levels in concrete slabs?

High moisture can result from insufficient concrete curing time, absence of vapor barriers, groundwater issues, plumbing leaks, or improper drainage around the building. - How long do moisture tests typically take to complete?

Calcium chloride tests require 72 hours, while RH testing needs at least 24 hours after drilling test holes. Electronic meter readings are instant but less accurate. - What should I do if moisture levels are too high?

Options include installing a moisture mitigation system, using moisture-resistant adhesives, choosing moisture-tolerant flooring, or waiting for the substrate to dry naturally.