Floor sample testing helps determine if flooring materials are suitable for your specific installation environment and requirements.

Understanding proper testing methods ensures you select the right flooring products while avoiding costly mistakes and potential failures down the road.

This guide covers essential floor testing procedures, required equipment, and key factors to evaluate when assessing flooring samples.

Key Testing Equipment

- Moisture meters (pin and pinless types)

- Calcium chloride test kits

- pH testing strips or meters

- Surface profile gauges

- Adhesive bond testers

- Temperature and humidity monitors

Essential Tests to Perform

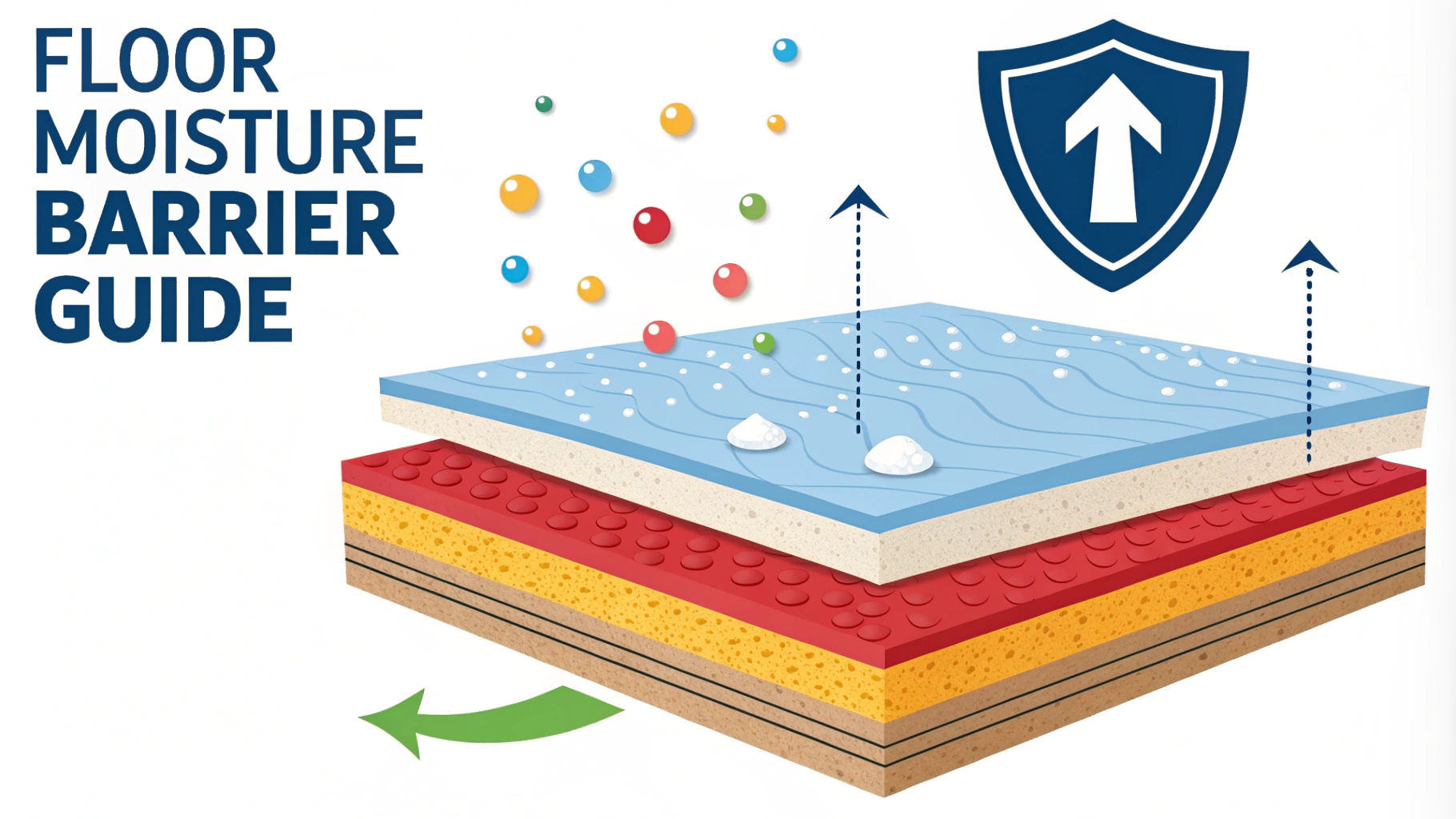

Moisture Testing

Use calcium chloride tests or relative humidity probes to measure concrete substrate moisture levels before installation.

Surface pH Testing

Test substrate pH levels using pH paper or digital meters to ensure compatibility with adhesives.

Bond Strength Testing

Conduct pull-off adhesion tests to verify proper bonding between flooring materials and substrates.

Environmental Conditioning

- Store samples in the installation area for 48-72 hours

- Maintain room temperature between 65-85°F

- Keep relative humidity between 35-65%

- Ensure proper air circulation

Visual and Physical Inspection

- Check for manufacturing defects

- Examine color consistency

- Test scratch resistance

- Assess surface texture

- Verify pattern alignment

Performance Testing

| Test Type | Purpose |

|---|---|

| Wear resistance | Evaluate durability under foot traffic |

| Chemical resistance | Test against common spills and cleaners |

| Slip resistance | Measure coefficient of friction |

Documentation Requirements

- Record test dates and conditions

- Document moisture readings

- Note surface preparation methods

- Keep photos of test locations

- Save manufacturer specifications

Professional Resources

Contact the National Wood Flooring Association (NWFA) at 800-422-4556 for technical guidance on testing procedures.

The Tile Council of North America (TCNA) offers detailed testing protocols – reach them at 864-646-8453.

Moving Forward with Installation

Only proceed with installation after all test results meet manufacturer specifications and industry standards.

Keep detailed records of all testing procedures and results for warranty purposes.

Consider hiring certified flooring inspectors for complex installations or when specific performance requirements must be met.

Installation Best Practices

- Follow manufacturer’s specific installation guidelines

- Use recommended adhesives and tools

- Maintain proper substrate preparation

- Document installation conditions

- Keep extra material for potential repairs

Maintenance Considerations

Routine Care

Establish proper cleaning protocols based on flooring type and test results to ensure longevity.

Preventive Measures

Implement protection methods like walk-off mats and furniture pads based on wear testing outcomes.

Troubleshooting Common Issues

- Address moisture problems immediately

- Document any surface irregularities

- Monitor environmental changes

- Track wear patterns

- Keep maintenance logs

Ensuring Long-Term Success

Thorough floor sample testing is crucial for successful installations. Maintain detailed records of all testing procedures, results, and ongoing maintenance for warranty protection and future reference.

Regular monitoring and adherence to manufacturer guidelines will maximize flooring performance and longevity. When in doubt, consult industry professionals to ensure proper testing and installation procedures.

FAQs

- What is floor sample testing and why is it important?

Testing floor samples ensures proper adhesion, moisture resistance, and durability before full installation. It helps prevent costly mistakes and confirms material compatibility with the subfloor. - How many floor samples should be tested for an accurate assessment?

A minimum of 3-5 samples per 1,000 square feet is recommended, with testing locations spread across different areas of the installation space to account for varying conditions. - What environmental conditions should be maintained during floor sample testing?

The room should maintain a temperature between 65-85°F (18-29°C) and relative humidity between 35-65% for at least 48 hours before, during, and after testing. - How long should floor samples be tested before installation?

Samples should be tested for a minimum of 24-48 hours, though some manufacturers recommend 72 hours for more accurate results, especially in high-moisture environments. - What tests should be performed on floor samples?

Essential tests include moisture content testing, pH testing of the subfloor, bond strength testing, and surface compatibility testing. - How do you properly conduct a moisture test on floor samples?

Use calcium chloride testing or relative humidity testing methods following ASTM F1869 or ASTM F2170 standards, respectively, and document results over the prescribed testing period. - What are the key indicators of a failed floor sample test?

Signs include adhesive failure, bubbling, curling edges, discoloration, or separation from the subfloor within the test period. - How should floor samples be stored before testing?

Store samples flat in the installation environment for at least 24-48 hours to allow acclimation to room temperature and humidity before beginning tests. - What documentation should be maintained during floor sample testing?

Record temperature, humidity, moisture readings, pH levels, visual observations, and any changes in sample condition throughout the testing period. - What role does subfloor preparation play in floor sample testing?

Proper subfloor preparation, including cleaning, leveling, and moisture mitigation if necessary, is crucial for accurate sample testing results.