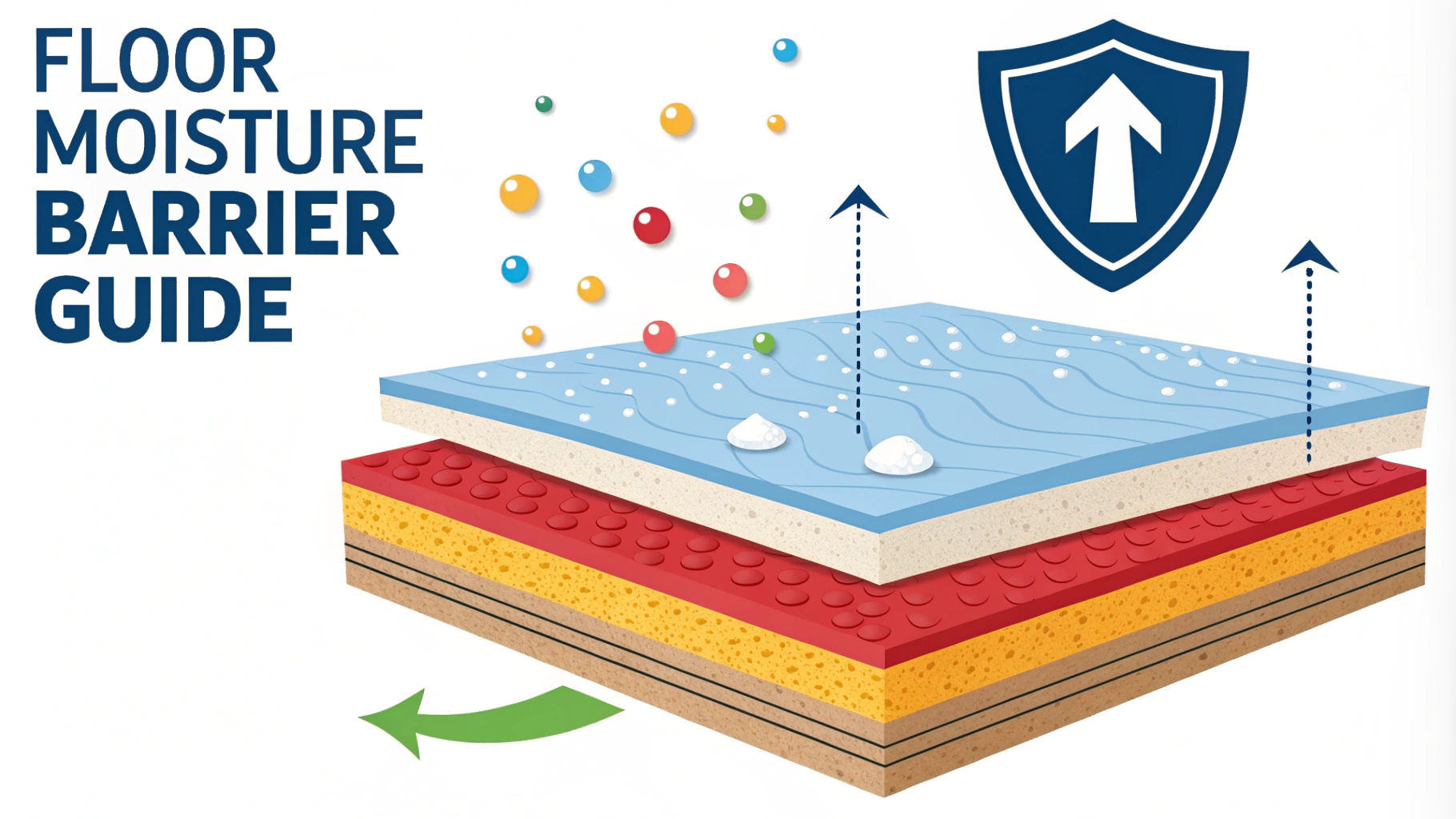

Floor sealants protect your flooring investment while enhancing its appearance and durability.

The right sealant creates a protective barrier against moisture, stains, and daily wear, extending the life of various flooring materials.

Understanding different sealant options helps homeowners and contractors make informed decisions for specific flooring types and use cases.

Common Types of Floor Sealants

- Polyurethane Sealants: Durable water-resistant coating, ideal for hardwood

- Epoxy Sealants: Heavy-duty protection for concrete and industrial floors

- Acrylic Sealants: Budget-friendly option for indoor residential use

- Penetrating Sealers: Best for natural stone and porous materials

Matching Sealants to Floor Types

| Floor Type | Recommended Sealant | Durability |

|---|---|---|

| Hardwood | Oil-based Polyurethane | 5-10 years |

| Concrete | Epoxy or Silicate | 10+ years |

| Natural Stone | Penetrating Sealer | 3-5 years |

| Tile | Silicone-based | 2-3 years |

Application Tips

- Clean and dry the surface thoroughly before application

- Test sealant on a small, hidden area first

- Apply thin, even coats using appropriate tools

- Follow manufacturer’s recommended drying times

- Maintain proper ventilation during application

Signs It’s Time to Reseal

- Water no longer beads on the surface

- Visible wear patterns in high-traffic areas

- Stains becoming harder to clean

- Changes in floor coloration or appearance

Professional vs DIY Application

Professional application typically costs $2-$5 per square foot but ensures proper preparation and application.

DIY application can save money but requires careful attention to detail and proper safety equipment.

Top Product Recommendations

- For Hardwood: Bona Mega HD Clear Satin ($45/gallon)

- For Concrete: Rust-Oleum EpoxyShield ($75/kit)

- For Natural Stone: StoneTech Professional Sealer ($35/quart)

- For Tile: Miracle Sealants 511 ($30/pint)

Maintenance and Care

- Clean floors regularly with appropriate cleaners

- Address spills immediately to prevent staining

- Use furniture pads to prevent scratches

- Schedule regular resealing based on wear patterns

Making Your Sealant Last

Regular maintenance and proper care can double the lifespan of your floor sealant.

Contact a local flooring professional for specific advice about your floor type and usage patterns (National Wood Flooring Association Directory).

Safety Considerations

- Wear protective gear including gloves and masks

- Ensure proper ventilation during application

- Store products away from heat sources

- Keep children and pets away until fully cured

- Dispose of materials according to local regulations

Common Application Mistakes

- Applying too thick of a coat

- Insufficient surface preparation

- Not following cure times

- Mixing incompatible products

- Skipping the test patch

Environmental Impact

Eco-Friendly Options

- Water-based sealants

- Low-VOC formulations

- Natural oil finishes

- Biodegradable products

Cost Analysis

| Project Size | DIY Cost | Professional Cost |

|---|---|---|

| Small (100-300 sq ft) | $100-300 | $200-1,500 |

| Medium (300-800 sq ft) | $300-800 | $600-4,000 |

| Large (800+ sq ft) | $800+ | $1,600+ |

Protecting Your Investment

Regular maintenance, proper sealant selection, and timely reapplication ensure long-lasting protection for your floors. Consider local climate conditions and usage patterns when developing your floor care strategy. Document your maintenance schedule and keep product information for future reference.

Connect with certified professionals and stay informed about new product developments to maximize your flooring investment’s longevity and appearance.

FAQs

- What are the main types of floor sealants available?

The main types include polyurethane, epoxy, acrylic, penetrating sealers, and water-based sealants. Each type offers different levels of protection and finish characteristics. - How long does floor sealant typically last?

Floor sealant durability varies by type: penetrating sealers last 3-5 years, water-based sealants 2-3 years, polyurethane 5-10 years, and epoxy sealants can last 10+ years with proper maintenance. - Which sealant is best for high-traffic commercial areas?

Epoxy and polyurethane sealants are ideal for high-traffic commercial areas due to their superior durability, chemical resistance, and ability to withstand heavy foot traffic and equipment. - Can I apply new sealant over old sealant?

Generally, old sealant should be completely removed before applying new sealant to ensure proper adhesion and prevent clouding or peeling. Surface preparation is crucial for optimal results. - What’s the difference between water-based and solvent-based sealants?

Water-based sealants have lower VOCs, are easier to clean up, and have minimal odor. Solvent-based sealants are more durable, provide better penetration, but have stronger odors and higher VOC content. - How do I maintain sealed floors?

Regular cleaning with pH-neutral cleaners, prompt spill cleanup, and avoiding harsh chemicals are essential. Reapplication intervals depend on wear patterns and sealant type used. - Which sealant is best for natural stone floors?

Penetrating sealers are ideal for natural stone as they protect while maintaining the stone’s natural appearance and allowing it to breathe, preventing moisture trapped beneath the surface. - What environmental factors affect sealant performance?

Temperature, humidity, UV exposure, moisture levels, and chemical exposure can all impact sealant performance and longevity. Indoor applications generally last longer than outdoor ones. - How long should I wait before walking on newly sealed floors?

Light foot traffic is typically possible after 24 hours, but full cure time varies: water-based sealants need 24-48 hours, while solvent-based ones may require 72 hours to fully cure. - What safety precautions should I take when applying floor sealant?

Ensure proper ventilation, wear protective equipment (respirator, gloves, eye protection), and keep the area free from sparks or flames, especially when using solvent-based products.