Floor edge treatments and finishing touches can transform an ordinary flooring installation into a professional, polished project.

Getting the edges and transitions right requires careful planning, proper tools, and attention to detail to achieve seamless results that will last.

This guide covers essential edge finishing techniques, material options, and expert tips to help complete your flooring project with a refined, high-end look.

Common Floor Edge Treatment Options

- Quarter Round Molding – Covers the expansion gap between flooring and baseboards

- Baseboards – Covers wall-floor joints while adding architectural detail

- T-Molding – Creates smooth transitions between rooms or different flooring types

- Reducer Strips – Bridges height differences between floor surfaces

- Stair Nosing – Provides finished edges and safety for steps

Material Selection Guide

| Material | Best Used For | Durability |

|---|---|---|

| Solid Wood | Traditional looks, paintable | High |

| MDF | Budget-friendly, smooth finish | Medium |

| PVC | Moisture-prone areas | High |

| Metal | Modern designs, heavy traffic | Very High |

Installation Tips

- Measure twice and cut once to minimize waste and errors

- Use a miter saw for precise angle cuts at corners

- Apply adhesive or nails according to manufacturer specifications

- Leave proper expansion gaps for wood flooring

- Color-match caulk for seamless appearances

Problem-Solving Solutions

- Uneven Walls: Use flexible quarter round or custom-cut baseboards

- Height Differences: Install reducer strips or transition moldings

- Gap Issues: Select wider trim pieces or double-stack moldings

- Corner Gaps: Apply paintable caulk before final painting

Maintenance and Care

Clean trim pieces regularly with appropriate cleaners for the material type.

Touch up paint or stain as needed to maintain appearance.

Check periodically for loose sections and repair promptly.

Professional Resources

For complex installations, contact the National Wood Flooring Association (www.nwfa.org) to find certified installers.

Local hardware stores often offer installation services and can recommend qualified contractors.

Next Steps for Your Project

Take detailed measurements of all edges and transitions requiring treatment.

Purchase materials with an extra 10% for waste and mistakes.

Consider renting professional-grade tools for precision cuts.

Safety Considerations

- Wear appropriate safety gear including eye protection and gloves

- Use power tools according to manufacturer guidelines

- Keep work area clean and well-ventilated

- Handle sharp trim pieces with care

- Follow proper lifting techniques for heavy materials

Cost Factors

Material Costs

- Basic MDF trim: $1-3 per linear foot

- Hardwood moldings: $3-8 per linear foot

- Metal transitions: $15-30 per piece

- Premium finishes: Additional 20-30%

Tool Requirements

- Miter saw: $200-500 purchase/$50 daily rental

- Nail gun: $150-300 purchase/$40 daily rental

- Hand tools: $50-100 total

Quality Control Checklist

- Verify all measurements before cutting

- Test fit pieces before final installation

- Check level and plumb on all installations

- Confirm proper expansion gaps

- Inspect all finishes for consistency

Creating a Professional Finish

Double-check all installations for secure attachment and proper alignment.

Remove any excess adhesive or caulk immediately.

Document maintenance requirements for future reference.

Take photos of completed work for warranty purposes.

Consider scheduling periodic inspections to maintain quality over time.

FAQs

- What are the most common types of floor edge treatments?

The most common floor edge treatments include bullnose, square edge, beveled edge, micro-beveled edge, and rounded edge profiles. - How long should I wait after installation before applying edge treatments to hardwood flooring?

Wait at least 48-72 hours after installation to allow the flooring to acclimate and any adhesives to fully cure before applying edge treatments. - What’s the difference between a micro-bevel and standard bevel edge?

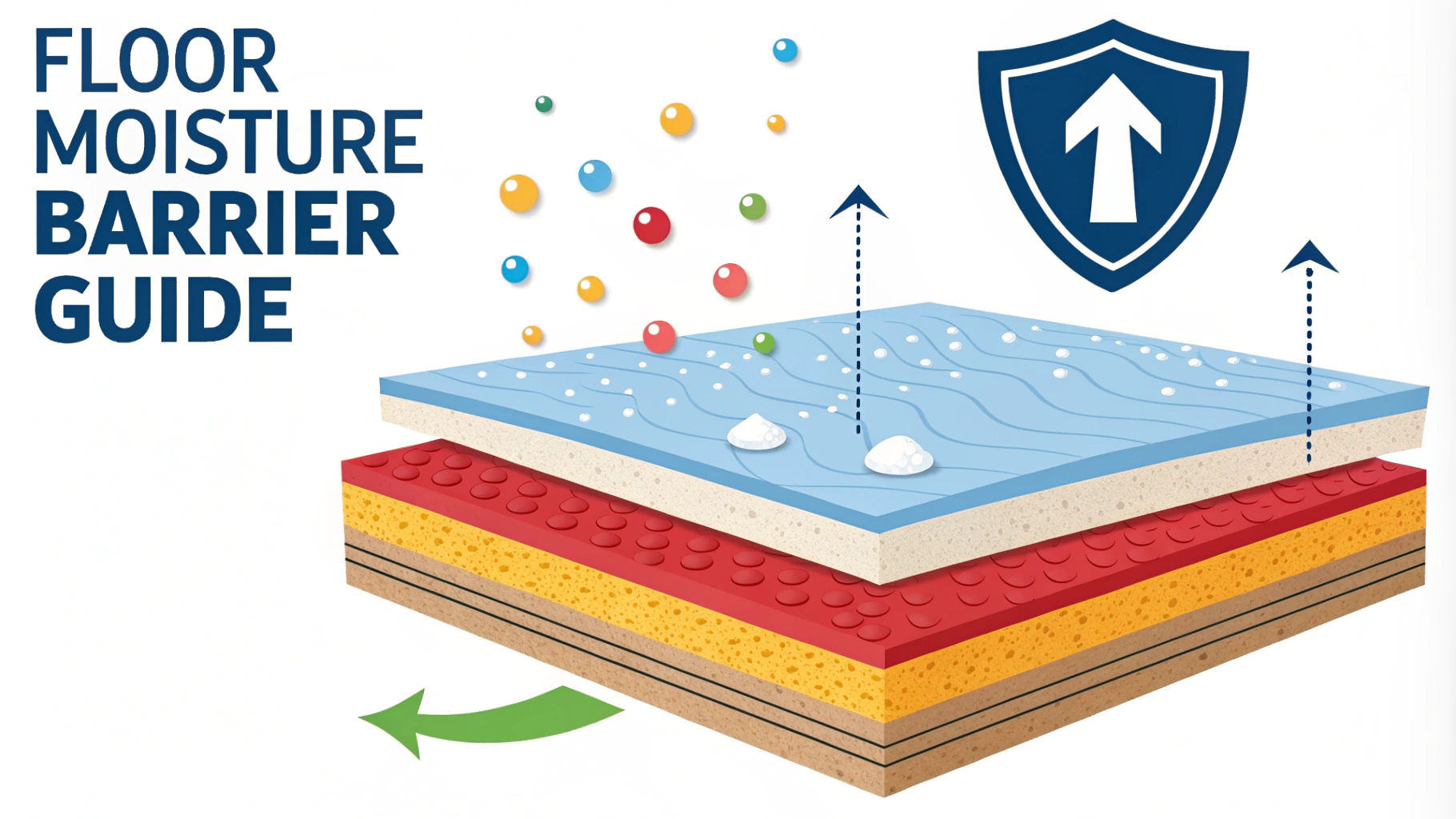

A micro-bevel has a slight 45-degree angle of about 1mm, while a standard bevel edge typically has a larger angle of 2-3mm, creating a more noticeable V-groove between boards. - Which edge treatment is best for high-moisture areas?

Square edges with proper sealing are best for high-moisture areas as they prevent water from collecting between boards, though micro-beveled edges can also work well when properly sealed. - How do I maintain edge treatments on hardwood floors?

Regular cleaning with appropriate wood cleaners, immediate water spill cleanup, and periodic resealing of the edges help maintain edge treatments effectively. - Can edge treatments be changed or refinished after installation?

Yes, edge treatments can be modified during refinishing, though options may be limited depending on the original profile and remaining board thickness. - What edge treatment is most suitable for commercial spaces?

Beveled or micro-beveled edges are typically best for commercial spaces as they help hide slight height variations and wear better under heavy foot traffic. - How do different edge treatments affect the appearance of a room?

Square edges create a smooth, seamless look ideal for modern spaces, while beveled edges emphasize individual boards for a more traditional appearance. Micro-beveled edges offer a subtle middle ground. - What tools are required for DIY edge treatment finishing?

Essential tools include sandpaper of various grits, edge sander, palm sander, wood filler, sealer, finish, and appropriate safety equipment including masks and eye protection. - How often should floor edge treatments be resealed?

Floor edge treatments typically need resealing every 3-5 years, depending on wear, traffic, and exposure to moisture.