Commercial kitchen flooring needs to meet strict safety, durability, and hygiene requirements while handling heavy foot traffic, equipment movements, and frequent cleaning.

The right flooring choice can prevent accidents, reduce maintenance costs, and help maintain health code compliance in professional kitchen environments.

This guide examines the best flooring options and requirements for commercial kitchens, helping owners make informed decisions that meet both regulatory standards and operational needs.

Essential Requirements for Commercial Kitchen Floors

- Slip-resistant surface (minimum coefficient of friction of 0.6)

- Chemical and stain resistance

- Temperature tolerance

- Impact and wear resistance

- Easy to clean and sanitize

- Water-resistant properties

- Load-bearing capacity

Top Commercial Kitchen Flooring Options

Epoxy Flooring

Epoxy floors provide excellent chemical resistance and can be customized with different slip-resistant textures.

Quarry Tiles

These dense ceramic tiles offer natural slip resistance and exceptional durability against heavy equipment.

Commercial Sheet Vinyl

Heat-welded vinyl sheets create a seamless surface that prevents water penetration and bacterial growth.

Installation and Maintenance Guidelines

Installation Requirements

- Proper substrate preparation

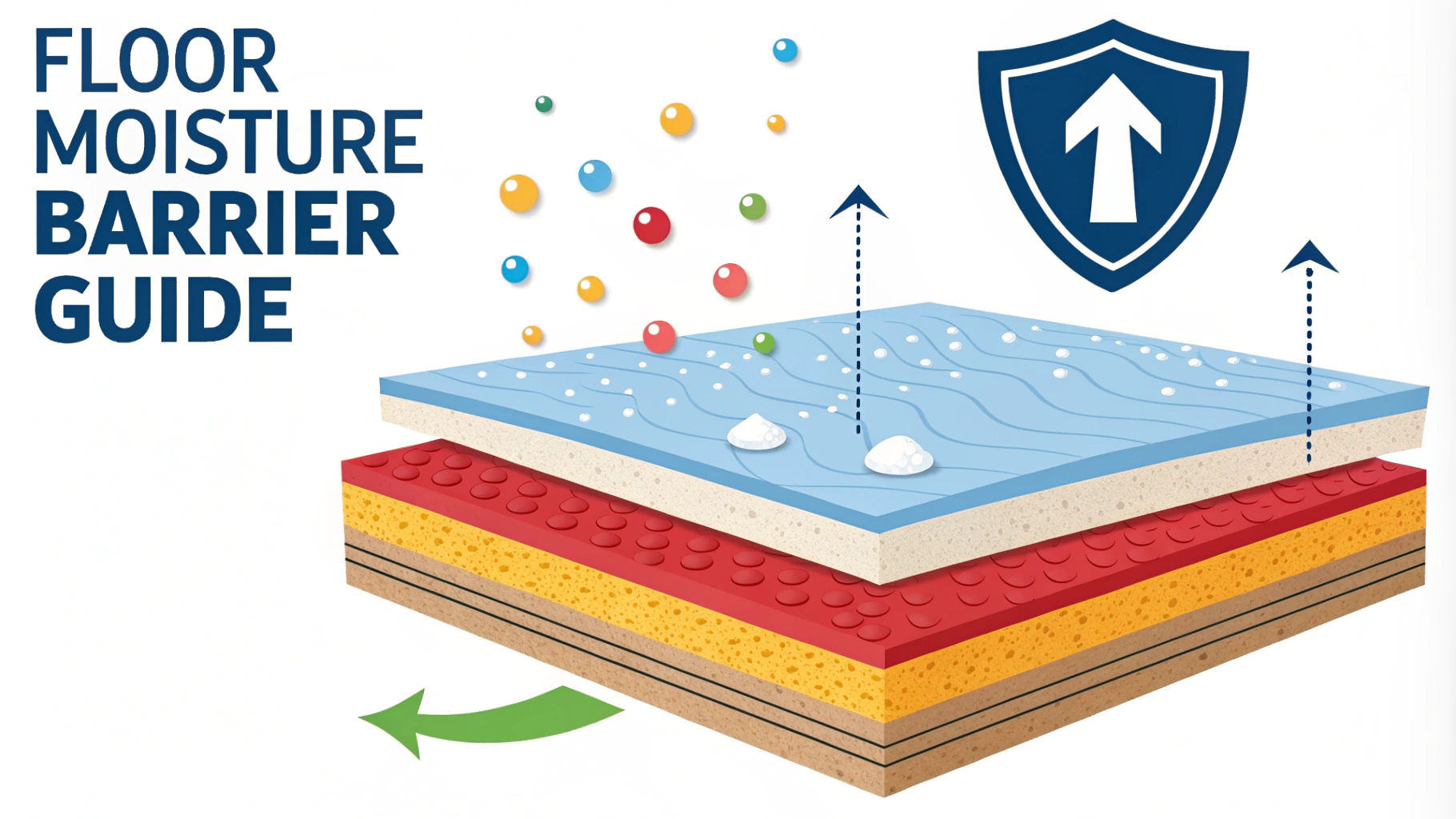

- Moisture barrier installation

- Professional grade adhesives

- Correct slope for drainage (1/8 inch per foot minimum)

Daily Maintenance

- Regular sweeping and mopping

- Immediate cleanup of spills

- Use of appropriate cleaning chemicals

- Regular inspection for damage

Cost Considerations

| Flooring Type | Cost per sq ft | Lifespan |

|---|---|---|

| Epoxy | $3-12 | 5-10 years |

| Quarry Tiles | $15-30 | 20+ years |

| Sheet Vinyl | $7-15 | 10-15 years |

Health and Safety Compliance

Commercial kitchen floors must meet FDA Food Code requirements and local health department regulations.

- OSHA slip-resistance standards

- Local building codes

- ADA accessibility requirements

- NSF International certification

Expert Tips for Long-Term Success

- Install floor drains every 100 square feet

- Use cove base for wall-floor junctions

- Consider thermal shock resistance in cooking areas

- Plan for future equipment layout changes

- Schedule professional deep cleaning quarterly

For specific regulations and requirements in your area, contact your local health department or a licensed commercial flooring contractor.

Environmental Impact and Sustainability

- Low-VOC materials options

- Recyclable flooring solutions

- Energy-efficient installation methods

- Sustainable cleaning practices

- Eco-friendly disposal considerations

Green Certification Options

Many modern flooring solutions offer LEED points and environmental certifications that can benefit both operations and marketing.

Common Problems and Solutions

Issue Prevention

- Regular joint inspection and repair

- Proper mat placement at entrances

- Temperature monitoring in critical areas

- Staff training on floor care

Quick Fixes

- Emergency repair kits for small damages

- Temporary non-slip treatments

- Spot cleaning protocols

- Impact protection measures

Making the Right Flooring Investment

Selecting the appropriate commercial kitchen flooring requires careful consideration of operational needs, budget constraints, and long-term maintenance requirements. Focus on safety features and durability while ensuring compliance with local regulations. Regular maintenance and proper installation by qualified professionals will maximize the return on investment and extend the flooring’s lifespan.

- Consider total lifecycle costs

- Evaluate warranty terms carefully

- Plan for future expansion

- Document maintenance procedures

- Build relationships with reliable contractors

FAQs

- What are the essential requirements for commercial kitchen flooring?

Commercial kitchen flooring must be slip-resistant, non-porous, easy to clean, durable, resistant to chemicals, and compliant with health and safety regulations. It should also withstand heavy foot traffic, thermal shock, and impact from equipment. - Which flooring materials are approved for commercial kitchens?

Approved materials include quarry tiles, epoxy resin, polyurethane cement, vinyl composite tiles (VCT), and commercial-grade sheet vinyl. Each must meet specific health department and safety standards. - How often should commercial kitchen flooring be replaced?

The lifespan varies by material: epoxy floors last 5-10 years, quarry tiles 15-20 years, and polyurethane cement 15-20 years. Regular maintenance and proper installation can extend these timeframes. - What slip resistance rating is required for commercial kitchen floors?

Commercial kitchen floors must have a minimum coefficient of friction (COF) of 0.42 according to OSHA standards. Many local health departments require higher ratings of 0.60 or above for wet areas. - Are there specific drainage requirements for commercial kitchen flooring?

Yes, floors must have a slope of approximately 1/8 inch per foot toward floor drains. Proper drainage prevents standing water and ensures sanitary conditions. - What temperature resistance is necessary for commercial kitchen flooring?

Commercial kitchen flooring must withstand temperatures from -20°F to 250°F (-29°C to 121°C) to handle both freezer areas and hot water cleaning without damage. - How thick should commercial kitchen flooring be?

Minimum thickness requirements vary by material: epoxy coating should be 6-8mm thick, quarry tiles 1/2 inch, and polyurethane cement 6-9mm for adequate durability and load-bearing capacity. - What are the cleaning requirements for commercial kitchen floors?

Floors must be cleaned daily with appropriate commercial-grade cleaners, degreased regularly, and deep cleaned periodically. The cleaning process must comply with local health department regulations and manufacturer specifications. - What impact resistance is required for commercial kitchen flooring?

Commercial kitchen flooring must withstand impact from dropped items and equipment weighing up to 2,000 pounds per square inch without cracking or permanent indentation. - Are there specific requirements for floor-to-wall transitions in commercial kitchens?

Yes, floors must have coved bases (curved transitions) between floor and wall, typically 4-6 inches high, to prevent bacterial growth and facilitate cleaning.