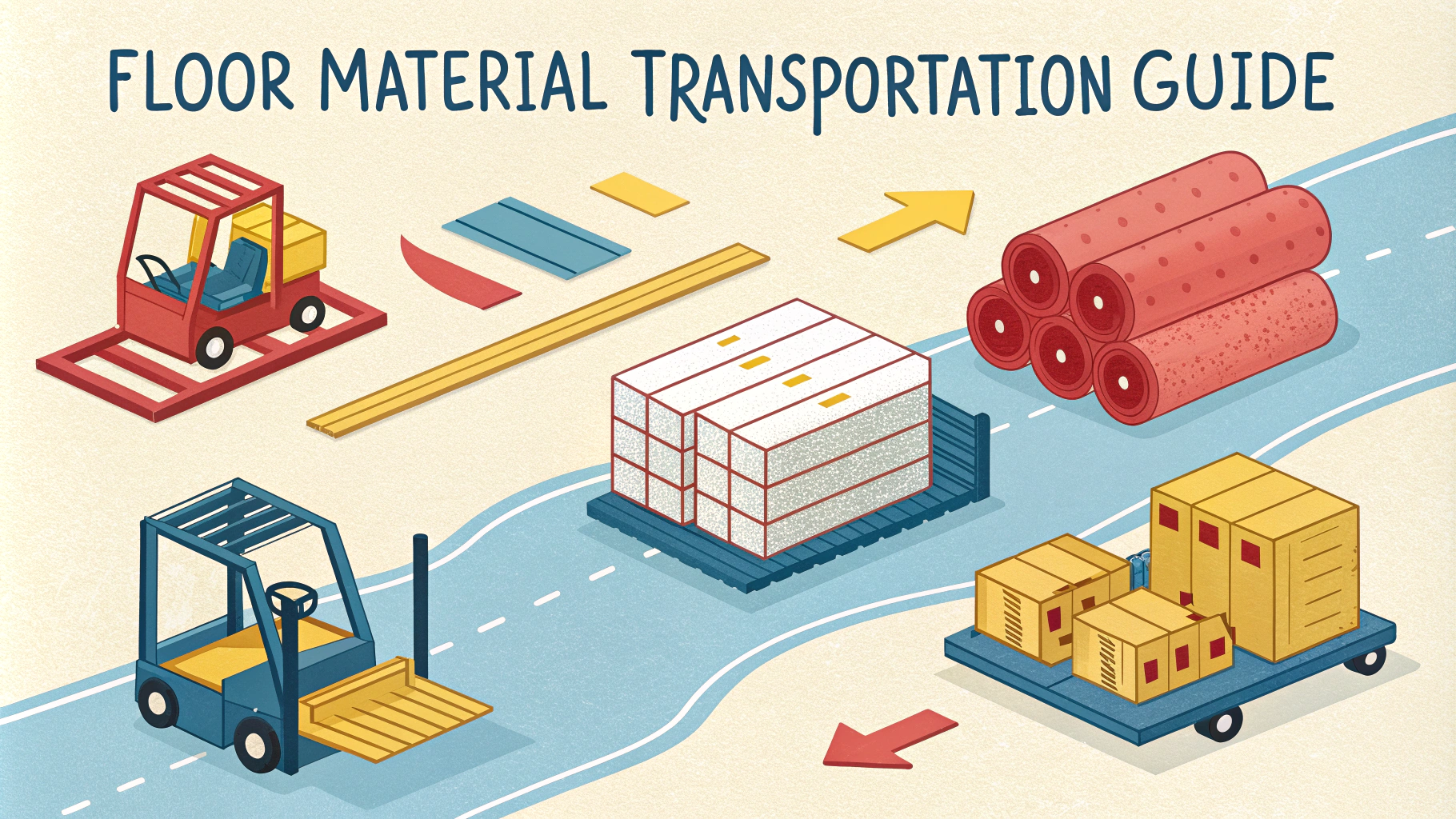

Moving flooring materials requires careful planning and proper handling techniques to prevent damage and ensure safety during transportation.

Different types of flooring materials have specific requirements for packaging, loading, and transport conditions that must be followed to maintain their quality.

This guide covers essential steps and best practices for safely transporting various flooring materials from pickup to delivery.

Preparation Before Transport

- Check weather forecasts to avoid rain/snow exposure

- Gather proper packaging materials (stretch wrap, corner protectors, moving blankets)

- Calculate total weight and required vehicle capacity

- Prepare a level loading area

- Have lifting equipment ready if needed

Material-Specific Guidelines

Hardwood Flooring

- Store flat and wrapped to prevent warping

- Keep boxes horizontal during transport

- Maintain consistent temperature (60-80°F)

- Use support beams for long boxes

Tile & Stone

- Stack boxes vertically on their long edge

- Place heavier boxes on bottom

- Use rubber mats between layers

- Secure loads with straps every 4 feet

Carpet & Vinyl

- Roll material tightly around solid core

- Stand rolls upright during transport

- Avoid stacking heavy items on top

- Protect edges with cardboard guards

Vehicle Requirements

| Material Type | Recommended Vehicle | Special Requirements |

|---|---|---|

| Hardwood | Enclosed truck | Climate control |

| Tile/Stone | Flatbed/Box truck | Heavy-duty suspension |

| Carpet/Vinyl | Van/Enclosed truck | Vertical storage space |

Safety Measures

- Use proper lifting techniques

- Wear safety gear (gloves, steel-toe boots)

- Secure load with appropriate straps

- Distribute weight evenly

- Check tie-downs regularly during transport

Professional Transport Services

Contact these reputable flooring material transport specialists:

- Flooring Logistics USA: 1-800-555-0123

- Premier Floor Transport: 1-877-555-4567

- National Floor Carriers: 1-888-555-7890

Moving Forward Successfully

Document any damage immediately upon delivery and report to the carrier or supplier within 24 hours.

Take photos before, during, and after transport for insurance purposes.

Keep delivery receipts and transportation documents for warranty validation.

Loading & Unloading Procedures

- Plan the loading sequence based on delivery order

- Use proper equipment (dollies, hand trucks, forklifts)

- Create stable load configurations

- Mark fragile items clearly

- Follow weight distribution guidelines

Common Transport Challenges

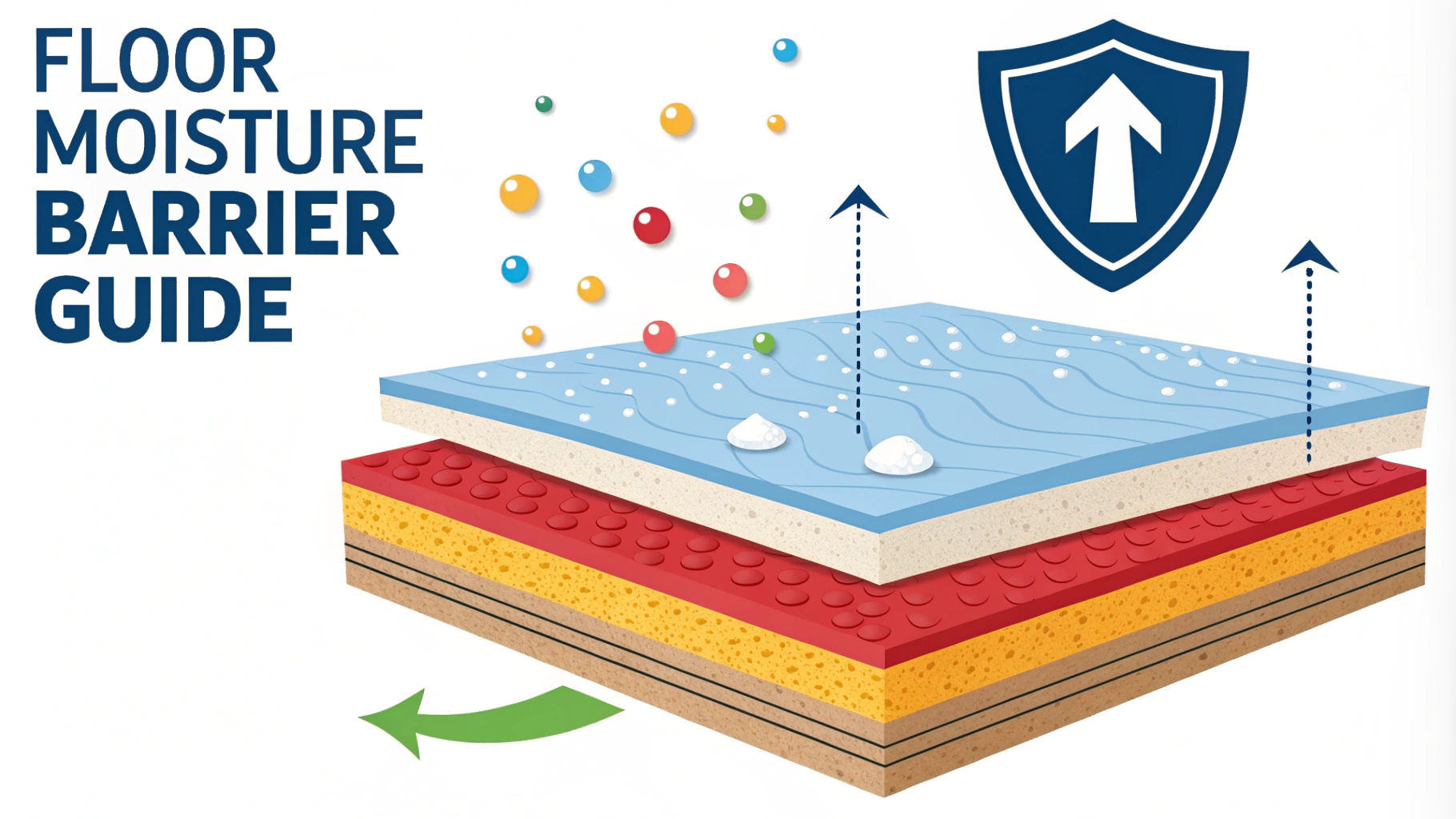

Weather Conditions

- Use waterproof covers during rain

- Avoid extreme temperature exposure

- Monitor humidity levels

- Plan alternate routes for severe weather

Handling Damage

- Inspect materials before loading

- Document pre-existing damage

- Use additional padding at pressure points

- Train staff on proper handling methods

Quality Assurance During Transport

- Monitor temperature control systems

- Check load security at regular intervals

- Maintain communication with dispatch

- Track delivery progress

- Update clients on status

Ensuring Long-Term Success in Flooring Transport

Following proper transport protocols protects both the materials and your investment. Regular training, equipment maintenance, and adherence to material-specific guidelines are essential for successful deliveries.

Remember to maintain detailed records of all shipments and continuously update procedures based on experience and changing industry standards.

Consider joining professional transportation associations to stay informed about best practices and new regulations in flooring material transport.

FAQs

- What’s the best way to protect flooring materials during transportation?

Wrap materials in protective blankets or plastic sheeting, secure them vertically on edge (not flat), and use straps to prevent shifting. For hardwood, maintain consistent temperature and humidity levels during transit. - How should tile materials be packaged for transportation?

Stack tiles vertically in their original packaging, use corner protectors, place on pallets, and secure with straps. Never lay boxes flat as this increases the risk of breakage. - What’s the ideal temperature range for transporting vinyl flooring?

Maintain temperatures between 55°F and 85°F (13°C-29°C) to prevent material warping or damage. Acclimate materials for 48 hours before installation. - How much overage should I account for when transporting flooring materials?

Calculate an additional 10-15% for hardwood and laminate, and 15-20% for tile to account for cuts, waste, and potential damage during transport. - What type of vehicle is best for transporting flooring materials?

Use an enclosed truck with climate control for sensitive materials like hardwood. The vehicle should have a flat bed and proper tie-down points for secure transport. - How should carpet rolls be transported?

Transport carpet rolls horizontally, never standing upright. Use carpet poles or cores to prevent creasing, and avoid stacking heavy items on top. - What insurance coverage is recommended when transporting flooring materials?

Obtain full-value coverage for the materials being transported, including coverage for damage from moisture, temperature changes, and physical impact. - Can different types of flooring materials be transported together?

Yes, but separate materials by type, weight, and fragility. Place heavier materials on the bottom, ensure proper spacing, and use appropriate barriers between different materials. - What documentation is needed when transporting flooring materials?

Maintain delivery receipts, material specifications, bill of lading, insurance documents, and any special handling instructions from manufacturers. - How should natural stone flooring be transported?

Transport on A-frames or specialized racks, secure with straps, use rubber padding between pieces, and ensure proper weight distribution in the vehicle.